|

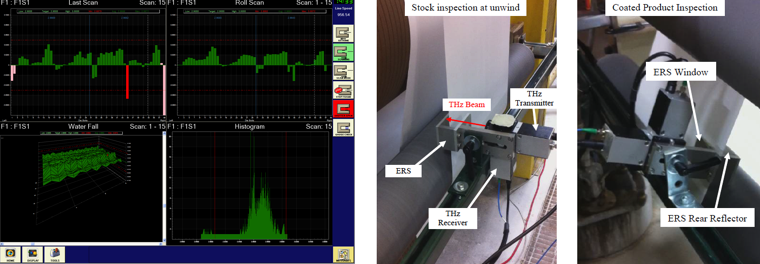

A very compact and simple sensor probe, its cost becomes lower and the

device operation becomes easier. This kind of sensor probe has been used to

detect the thickness of the pipe wall in the plastic pipe production line. In

addition, this device is also very suitable for measuring coatings on fiber

composites.

Terahertz's new sensor unique features and value

The terahertz sensor is a safe non-radioactive in-line measurement solution

for a variety of applications such as multilayer plastic sheet extrusion,

multilayer foam extrusion, rubber tire calendering, multi-layer conveyor

belts, roofing materials, single Roofing (such as TPO or EPDM) and many other

uses. Terahertz sensors offer a variety of unique new measurement

capabilities that cannot be achieved in any other single sensor solution. The

sensor can measure thickness, grammage and density simultaneously, while

other solutions require a physical thickness sensor and another physical

grammage sensor to measure density. Terahertz sensors also enable multilayer

measurements of materials, providing intuitive thickness measurements and

insensitivity to color or additives without any specific calibration of the

product.

The terahertz sensor can be used as a single-sided reflective sensor to

highly accurately measure the thickness of a multilayer sheet structure and

can be used to measure all types of materials other than metals and other

conductive materials.

Another application of this new terahertz sensor probe is to verify

paints and coatings on fiber reinforced composites. People can use eddy

current testing technology to detect some metal-based materials, such as the

detection of metal flakes in the automotive industry; but eddy current

testing technology is not suitable for poorly conductive fiber composite

materials. Therefore, with the wide application of composite materials in the

automotive, aerospace, aerospace and energy fields, people urgently need a

reliable detection method. And this new type of terahertz sensor probe can

solve this problem. Terahertz technology will achieve more success in the

coming years and soon become a mainstream non-destructive testing tool.

Terahertz sensor advantages:

New terahertz technology combined with the most advanced design;

Only one sensor can be used to simultaneously measure total thickness,

grammage, density, and layer detection technology;

Single-layer or surface PP layer, EVOH barrier layer, bottom PP layer and

other multi-layer product structure accurate online measurement;

Safe and non-radioactive, without environmental regulatory approval (unlike

isotope radioactive sources or X-rays);

To better control and improve product quality, save raw materials, increase

production, and reduce scrap.

|

" continuous innovation, excellent quality; Continuous improvement, customer satisfaction. "more >>

" continuous innovation, excellent quality; Continuous improvement, customer satisfaction. "more >> " continuous innovation, excellent quality; Continuous improvement, customer satisfaction. "more >>

" continuous innovation, excellent quality; Continuous improvement, customer satisfaction. "more >> " continuous innovation, excellent quality; Continuous improvement, customer satisfaction. "more >>

" continuous innovation, excellent quality; Continuous improvement, customer satisfaction. "more >> " continuous innovation, excellent quality; Continuous improvement, customer satisfaction. "more >>

" continuous innovation, excellent quality; Continuous improvement, customer satisfaction. "more >> " continuous innovation, excellent quality; Continuous improvement, customer satisfaction. "more >>

" continuous innovation, excellent quality; Continuous improvement, customer satisfaction. "more >>